RAPIDPROTOTYPEDSHOE

Rapidprototypedshoe / 2010

Rapidprototypedshoe / 2010

Mechanical Couture; Fashioning a New Order, 14 October 2010 – 8 January 2011

Design Museum Holon, Israel

Curators: Curatorsquared; Ginger Gregg Duggan and Judith Hoos Fox

Other exhibitors; Dai Fujiwara, Shelley Fox, Ying Gao

and Simon Thorogood

www.dmh.org.il

Rapidprototypedshoe is made using an additive manufacturing technology in which successive layers of a photopolymer material are UV cured. The shoe is built in one go, but is comprised of two materials, which are organised into different microscopic structures, thereby enabling different material properties. As a result, the shoe has both flexible and rigid sections. The shoe has been designed to be disassembled for the purpose of replacing parts, despite having never been assembled in the first place.

When moving from rapid prototyping to rapid manufacturing, inherent construction possibilities and aesthetics of the production method needs to be explored. Certain design and production details such as the punch holes and screws in this design are not a derivative of this production method, but still make constructive sense.

Construct #2 / 2010

Construct #2 shows the step-by-step digital procedure for creating Rapidprototypedshoe. The series includes microscopic images of the material Rapidprototypedshoe has been made from, in both a liquid and cured state.

Shoe last. Digitising shoe last.

Digitising shoe last. VeroBlack material cartridge for Objet's Connex500 multi-material 3D printing machine.

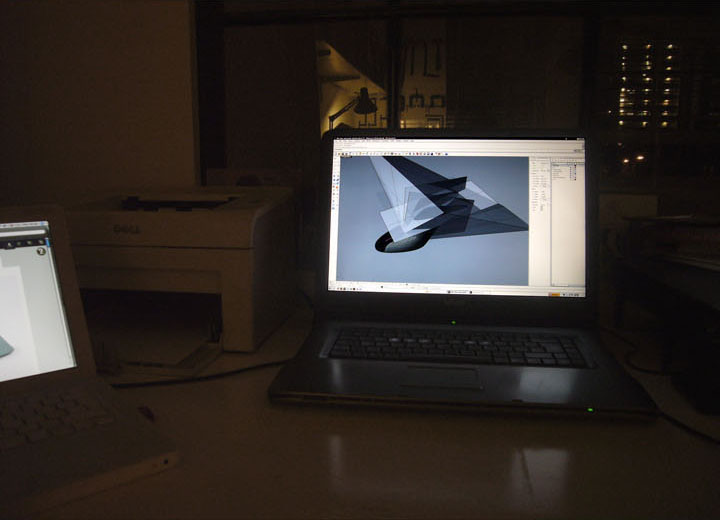

VeroBlack material cartridge for Objet's Connex500 multi-material 3D printing machine. Creating 3D file in Rhino.

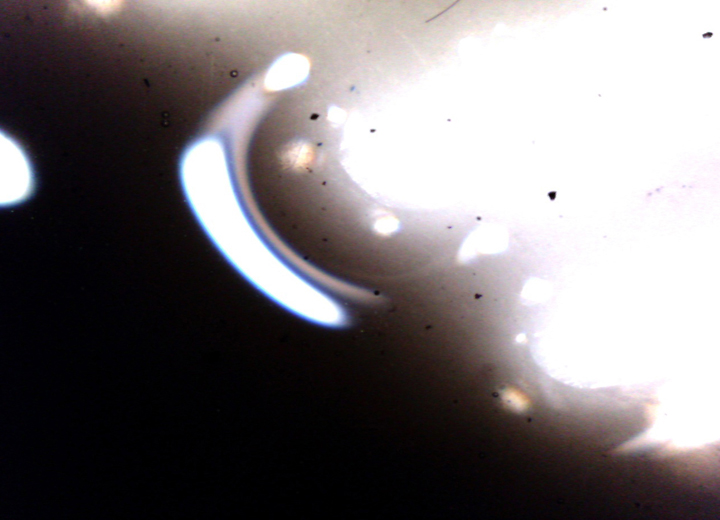

Creating 3D file in Rhino. Digital microscopic image 50X zoom of VeroBlack material in liquid state.

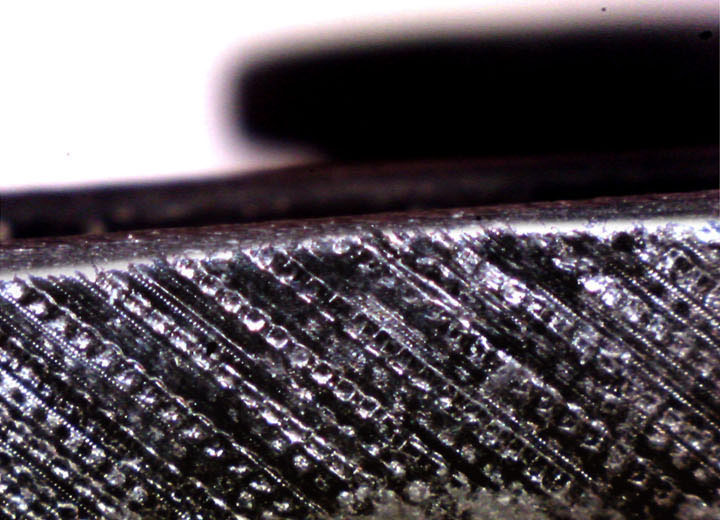

Digital microscopic image 50X zoom of VeroBlack material in liquid state. Digital microscopic image 50X zoom of VeroBlack material in built state.

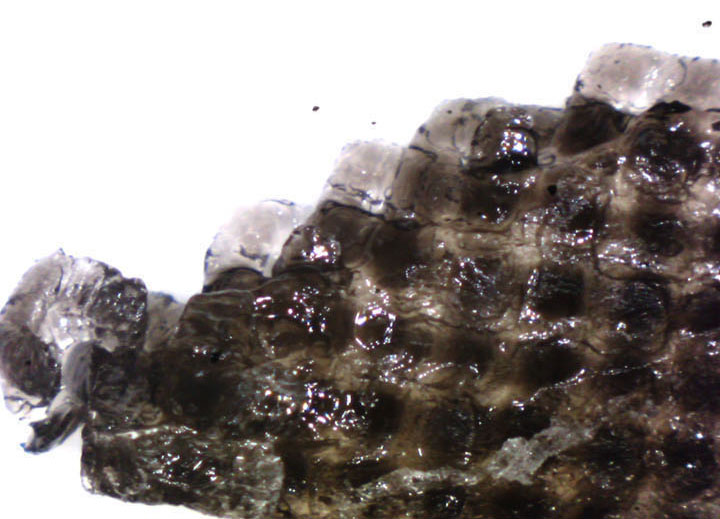

Digital microscopic image 50X zoom of VeroBlack material in built state. Digital microscopic image 50X zoom of VeroBlack scaffold material.

Digital microscopic image 50X zoom of VeroBlack scaffold material.  Rapidprototypedshoe.

Rapidprototypedshoe. Exhibition shot, Design Museum Holon.

Exhibition shot, Design Museum Holon.

________________________________________________________________________________________________________________________

© Marloes ten Bhömer 2000-2023